Is Your HPLC /UPLC Waste Collection OSHA Compliant?

What Hazards are Associated with your HPLC / UPLC and LCMS/MS?

High-Performance Liquid Chromatography (HPLC), or Ultra High-Pressure Liquid Chromatography (UPLC) is a process used by synthetic or analytical chemists to separate, identify and quantify each component in a mixture. This process can help in many different applications such as research and development, analytical chemistry, pharmaceutical manufacturing, research of components in complex biological samples, and medicinal purposes such as vitamin levels in blood serum samples.

While being a highly effective and common process in laboratories, HPLC /UPLC also poses risks to employee safety and health if not handled properly. The following are common tasks and their associated risks:

|

Task or Scenario |

Hazard/s |

Associated Harm |

|

Solvent used as mobile phase |

Toxic, Flammable |

|

|

Flowing liquids in HPLC are under high pressure |

|

|

|

Analyzing Samples |

|

|

|

Solvent and Sample Spills |

|

|

How can I prevent these hazards from happening?

While many of the hazards listed above can be avoided through proper training and Personal Protective Equipment, using correct laboratory equipment is a must. The containers used to provide the necessary solvents for HPLC, when not properly capped, release toxic fumes into the laboratory, polluting the environment. Some laboratories will haphazardly attempt to tape up the bottle closures around the tubing. While this is better than nothing at all, it isn’t OSHA compliant and it still doesn’t prevent pollution nor help keep the chemicals intact if the bottle is knocked over. Moreover, the solvent bottle becomes available to potential sources of contamination which may affect the results of the experiment. This is especially concerning when HPLC is used in tandem with Mass Spectrometer.

How can CP Lab Safety help you be safer and have better results?

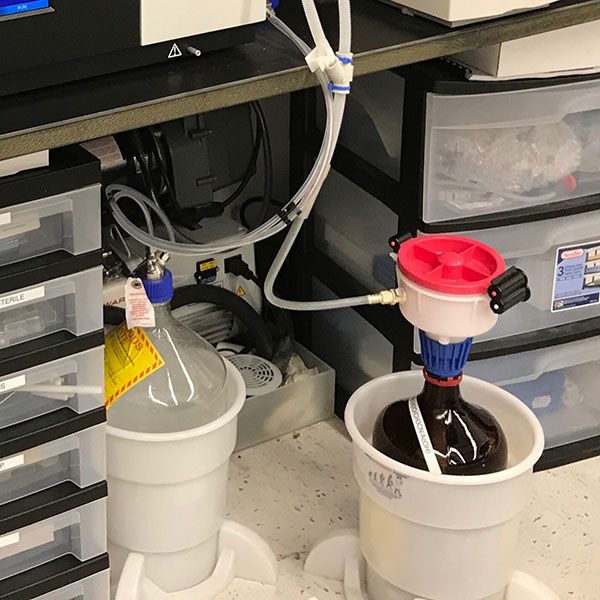

Our Classic Port Caps are the solution to this workplace hazard. Made from Polypropylene with a PTFE insert, they are compatible with most solvents and they’re designed to fit standard GL45 and GL38 glass bottles, as well as Nalgene 38-430 plastic bottles – the most commonly used containers for HPLC. The ¼-28 Ports support 1/8” (Outer Diameter) tubing, machined at a 10-degree angle. These Port Caps help with OSHA compliance (29 CFR: 1910.1450) through prevention of harmful off-gassing and ensuring proper delivery and waste containment of chemicals.

All ECO Funnels and Port Caps are customizable. To learn more about our Port Caps and how you can become more compliant, please contact us via email: info@cplabsafety.com or call us at (888) 322-5722. You can also browse our wide selection of Port Caps.

Recent Posts

-

Disinfecting Surfaces in the Era of Covid and EPA Registered Commercial Disinfectants and Viricides

The disinfection of surfaces at home, in public spaces, and in hospitals and clinics needs to be a …15th Jan 2023 -

Working with Inorganic Acids in the Laboratory: A Practical Guide

Working with Inorganic Acids in the Laboratory Acids are of great importance in the laboratory and a …5th Jan 2023 -

The Top 12 Drinking Water Contaminants

1.Lead- from older plumbing systems pre-1986, when lead pipes, solder, and components were banned. …14th Dec 2022